Rescanoe

A rescue device to help un-flip capsized canoes safely and efficiently.

CHALLENGE

ENGS 21: Introduction to Engineering challenges students to build a fully-functional product and engage in the full product design process to identify a need, build a working prototype, and test it with users.

Conversations with students in the Ledyard Canoe Club led us to our focus area: capsized canoes. It is difficult and potentially dangerous to right a flipped canoe, especially in deep or cold water.

OUTCOME

- Our device can ‘un-capsize’ a canoe using CO2-powered floatation devices and can also help the user re-enter with a specialized ladder.

- 10 week project involving user research, rapid prototyping, quantitative usability testing, jumping into the Connecticut river in October, and (when that proved too chilly) canoeing in the pool.

PROJECT INFO

Team

Me (designer & engineer)

Noah Daniel (designer & engineer)

Omar Alsaeed (designer & engineer)

Nicole Evans (designer & engineer)

Skills

Needfinding

Physical prototyping

Prototype testing

Data collection

CAD

Timeline

10 weeks (2019)

BACKGROUND

“In my 37 years of running canoes, the number one thing that people are afraid of is turning over”

-Mike Mills, Buffalo Outdoor Center

Picture this: you’ve capsized your canoe in the middle of a lake, almost half a mile from shore. It’s cold, you’re exhausted, and the only way to drain it is to lift it above the water. You don’t have the strength to do this, but swimming back is also too tiring. Hopefully you’re wearing a life vest and are with other people who can help, but this situation would quickly turn dangerous if not.

This is the problem we stumbled upon after talking with students in the Ledyard Canoe Club. It is not possible to drain and right a canoe with only one person, presenting obvious safety concerns for elderly, disabled, or solo paddlers in deep or cold water.

DESIGN PROCESS

Capsizing is common, and so is canoing alone

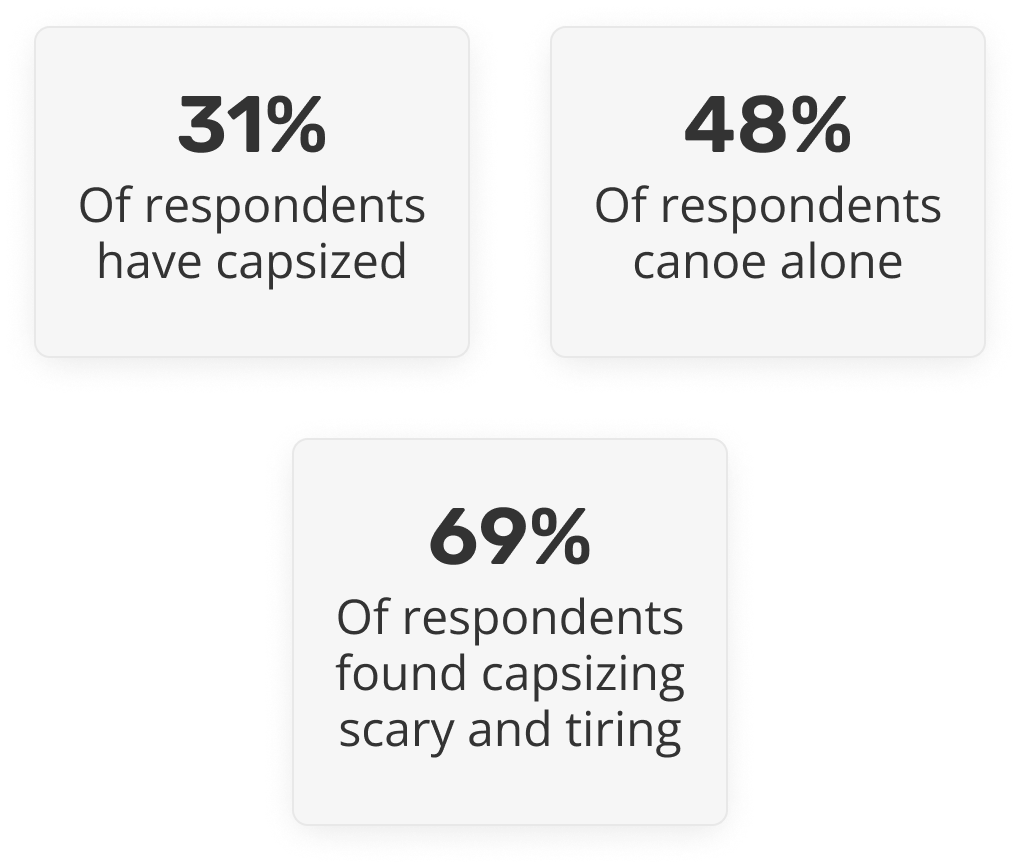

We surveyed 48 students and found that they echoed many of the sentiments we heard from Ledyard members. In short, capsizing a canoe is an unpleasant experience that can become more scary for those who canoe solo.

COMPETITIVE RESEARCH

Existing solutions are not practical for one person in dangerous water conditions, and none assist with re-entry.

T-Rescue

A second canoe lifts the flipped canoe to drain it. 50% of surveyed students have used this method, but it’s physically demanding and cannot be done alone.

Drag to shore

Paddler swims with the canoe to shore, used by 32% of surveyed students. This presents obvious safety concerns in cold, fast moving, or large bodies of water.

Float bags

Pre-inflated buoyant bags placed in the bow and stern. Not commonly used, still require effort to overturn the canoe, and take up a lot of space.

BRAINSTORM

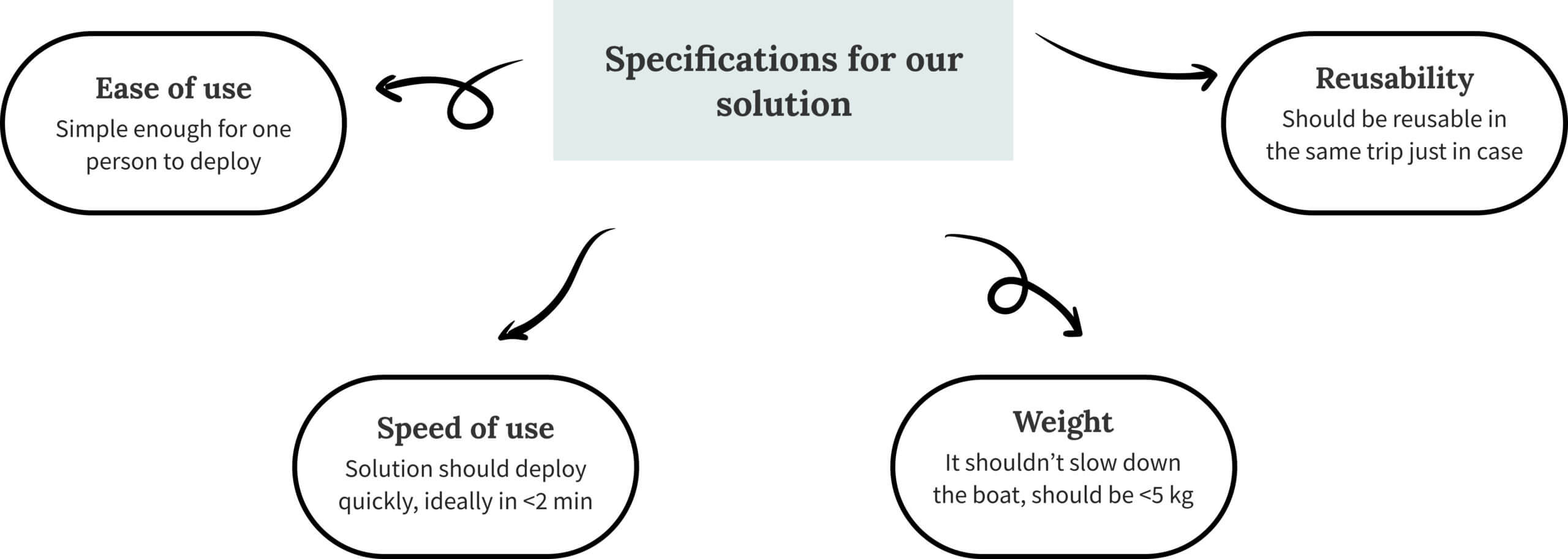

- We narrowed to the most feasible solutions and created this alternatives matrix to decide on a direction for prototyping.The highest scoring option was an attachable inflatable.

- By far, the most appealing inflatable option was a CO2-cartridge powered inflatable. CO2 inflators are the state of the art for many rescue devices because they are waterproof, highly portable, and offer unparalleled speed. For maximum safety, we knew we would be focused on designing a CO2-powered inflatable device.

PROTOTYPING

We designed guided by testing

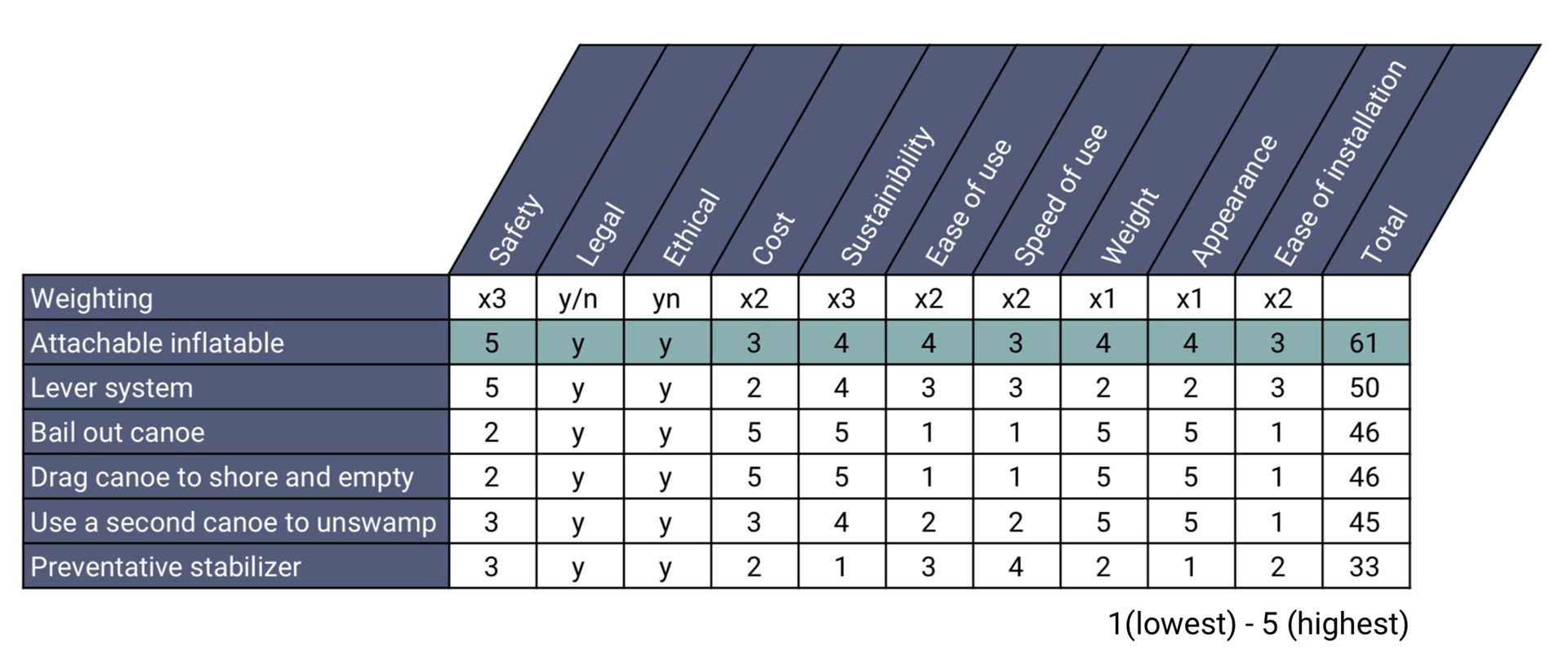

We outfitted this 3D printed canoe with different foam models to mimic the functionality of deployed inflatables. We recorded the force required to un-flip the canoe, the volume of water in the canoe after un-flipping, and the weight of the device.

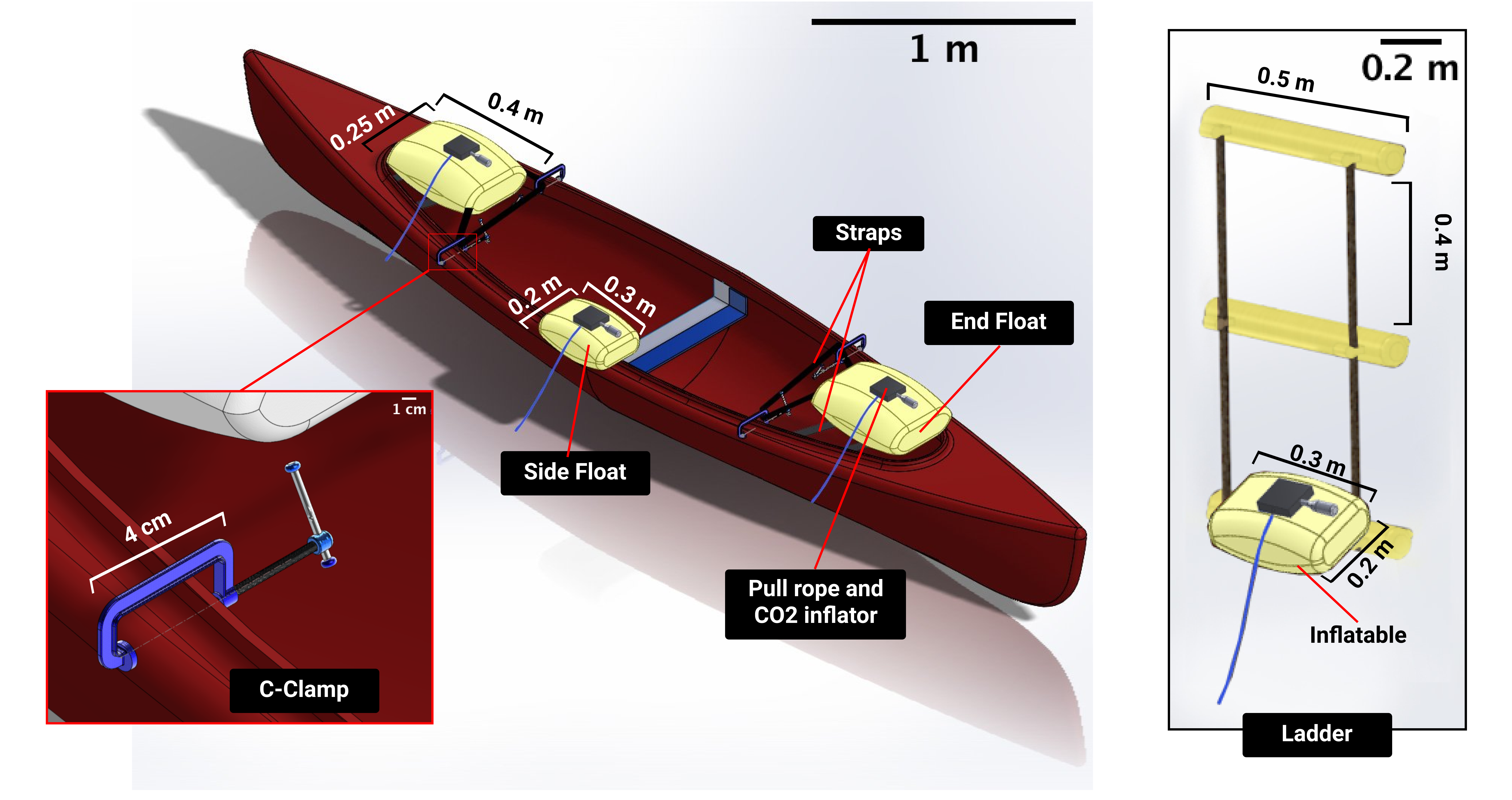

The designs with elevated end floats and side floats (D, F, G) performed the best. They required the least force to un-flip, collected the least water after flipping, and were relatively light.

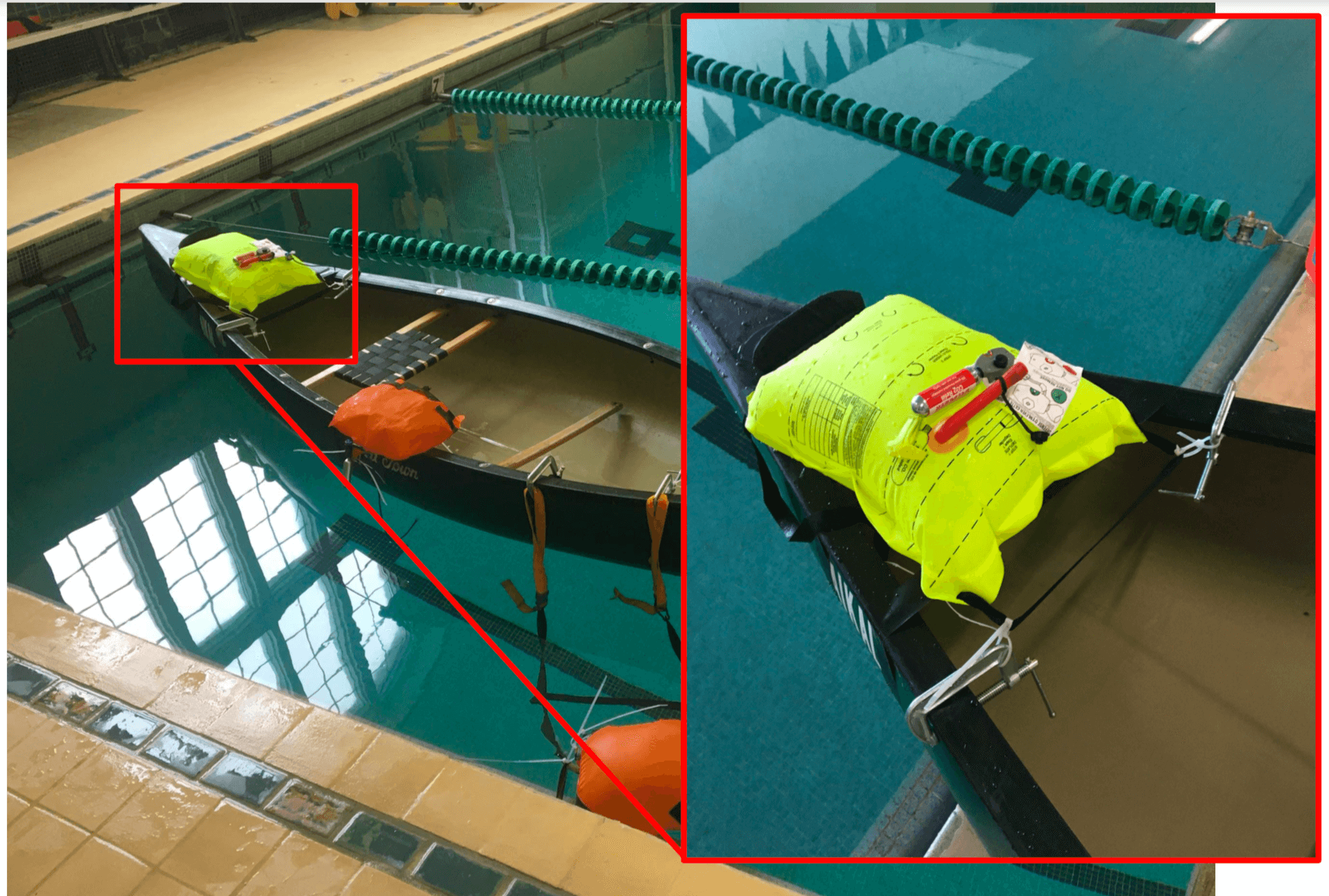

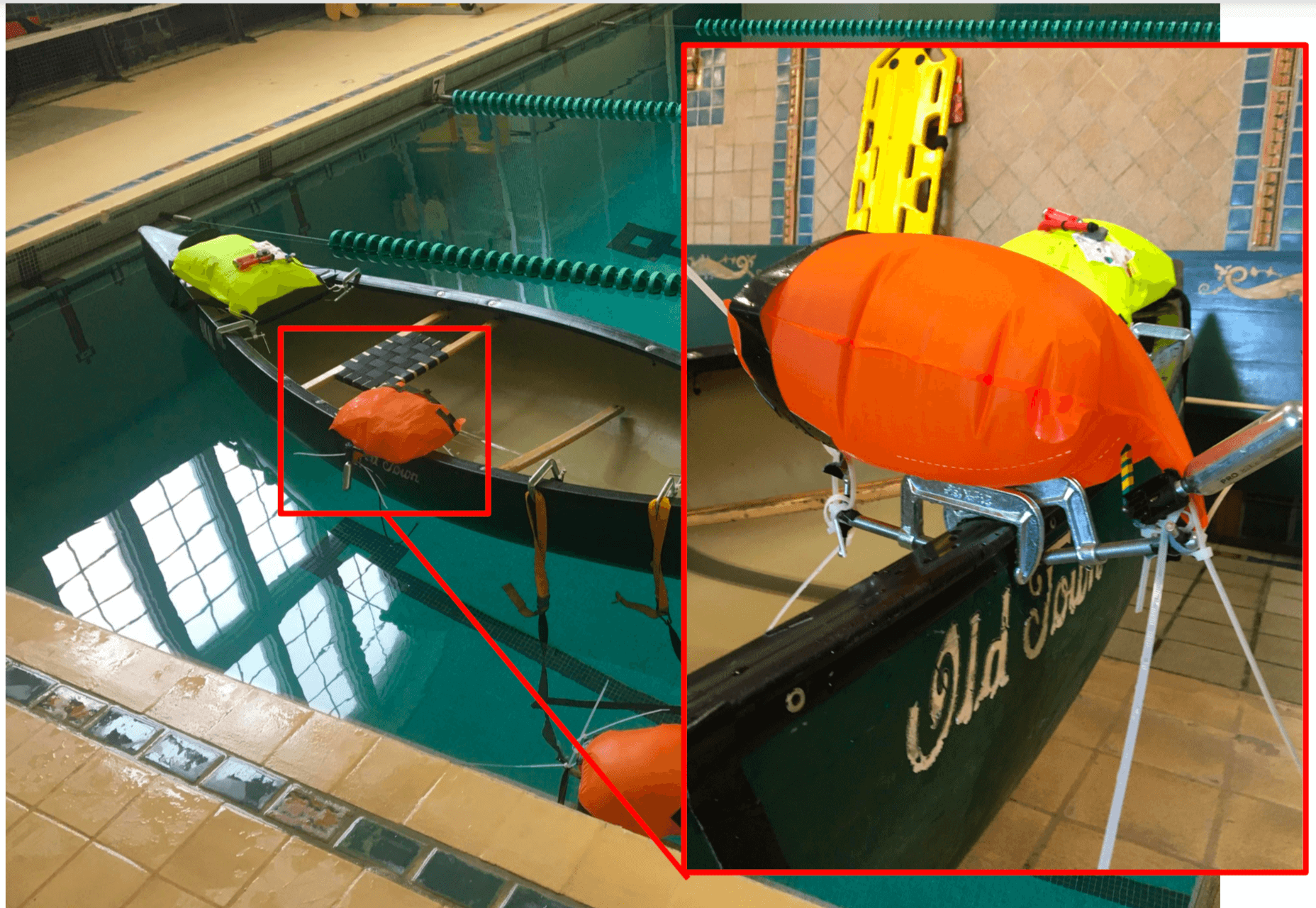

Functional prototype

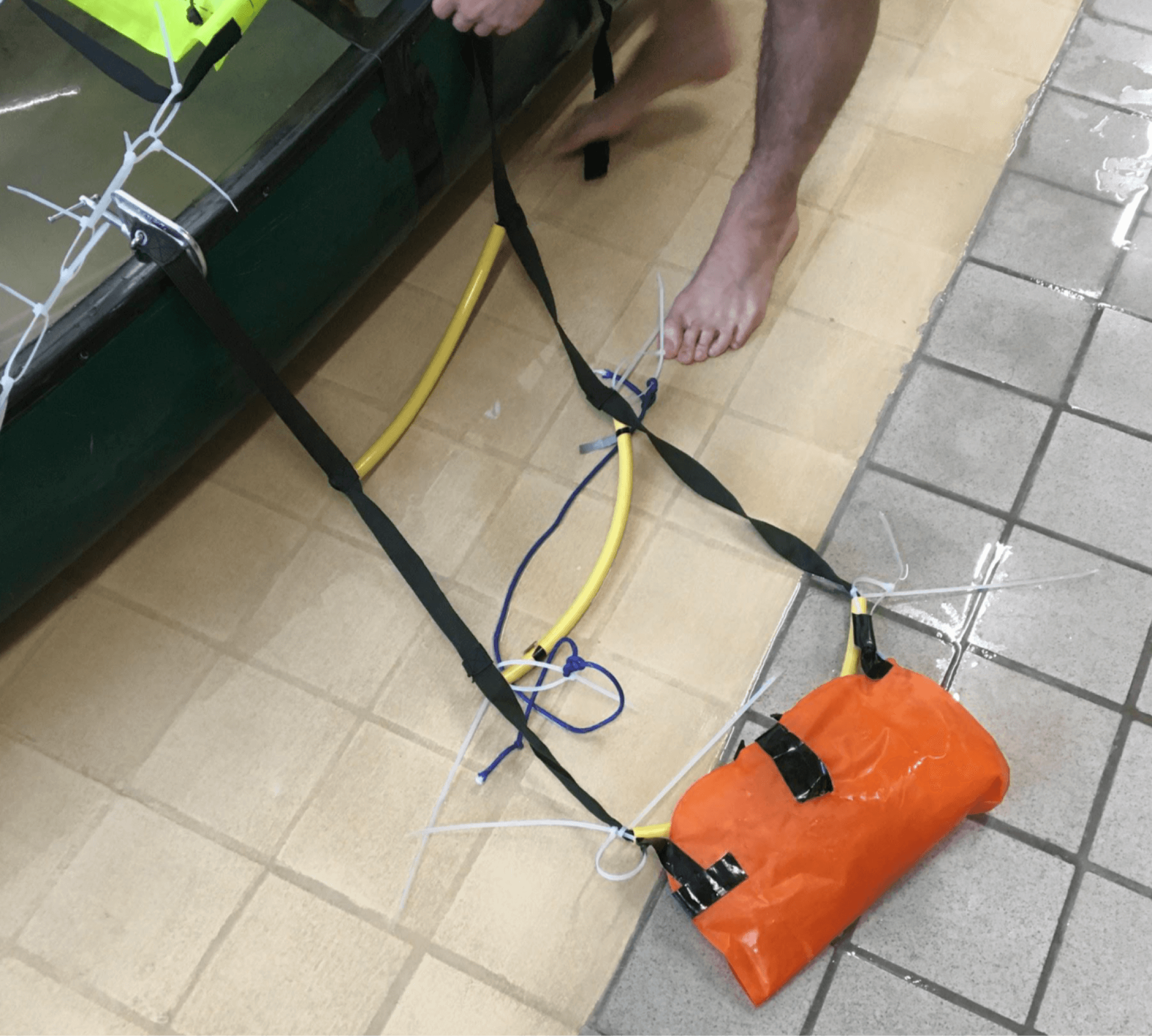

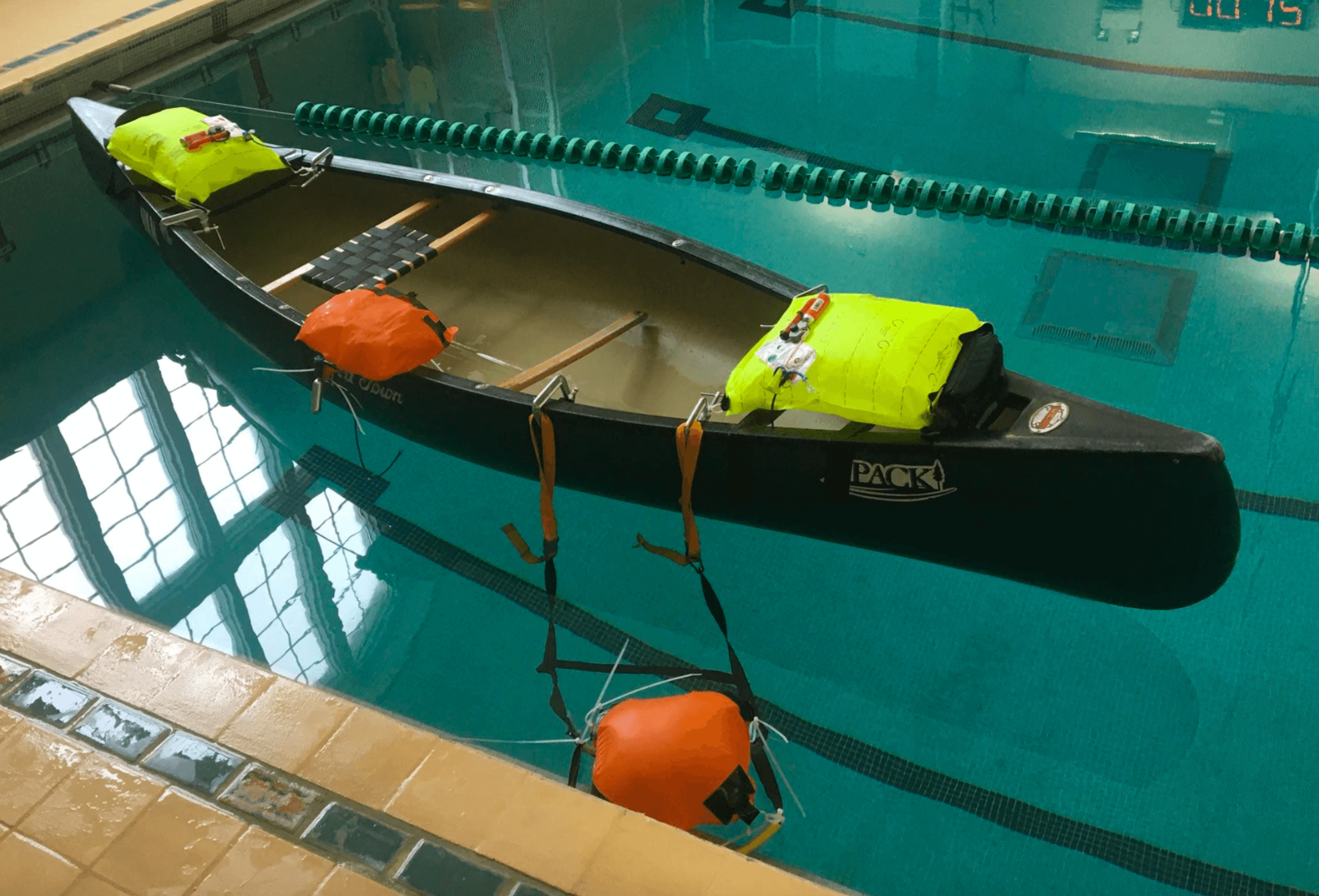

With this prototype, we were able to test a full size version of the inflatable device by attaching elevated float bags and a side float to a full-sized single person canoe (the Discovery 119).

This rough model helped us to better understand the behavior of the device before we committed to purchasing the CO2 inflatables.

DESIGN CHALLENGE

How to get back in the canoe?

After testing the inflatables, we still had to determine a mechanism for re-entry. Attempting to climb into a canoe from the water, even with a ladder on the side, would always result in the canoe capsizing without another person balancing the weight.

We challenged ourselves to enable solo re-entry through our solution.

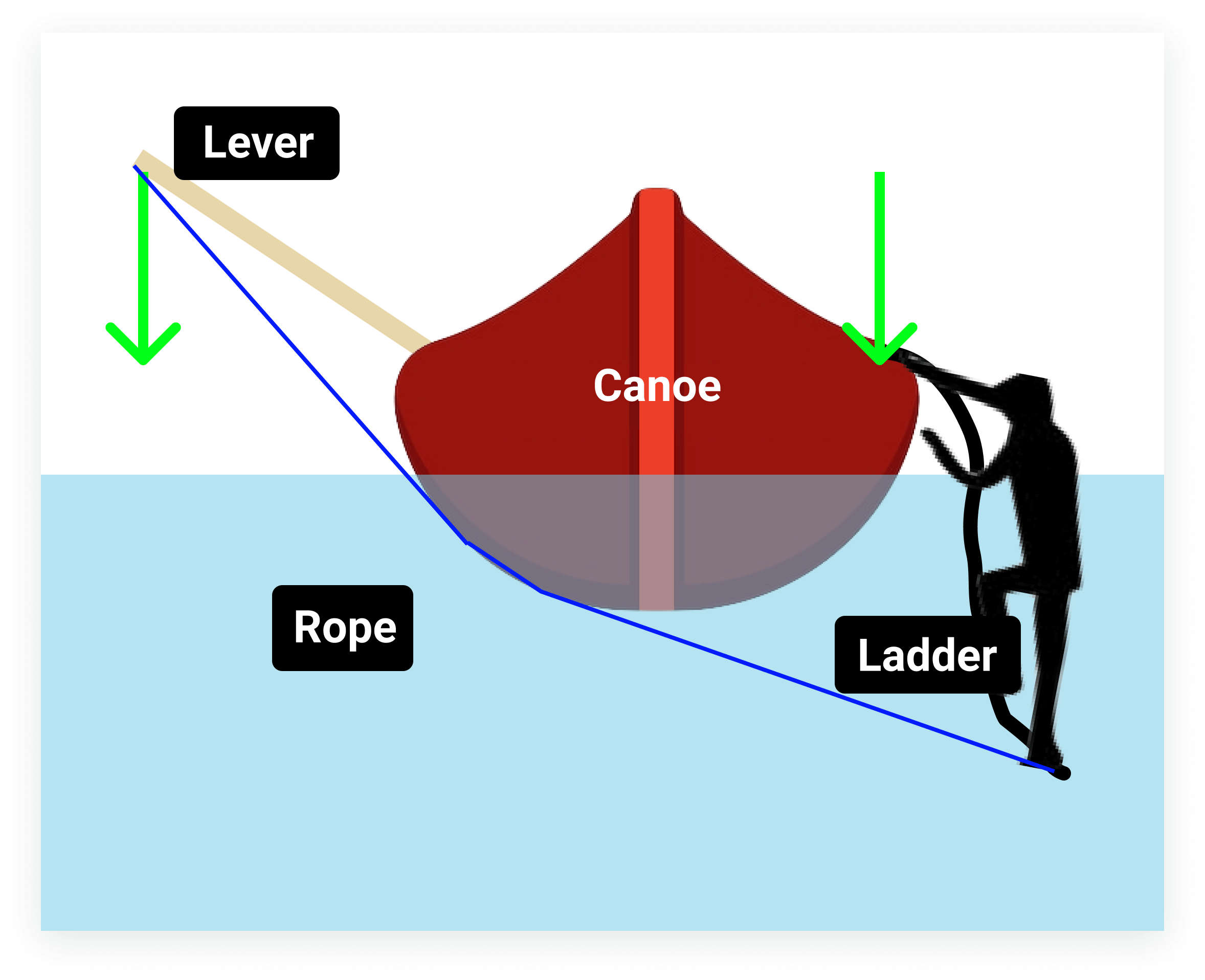

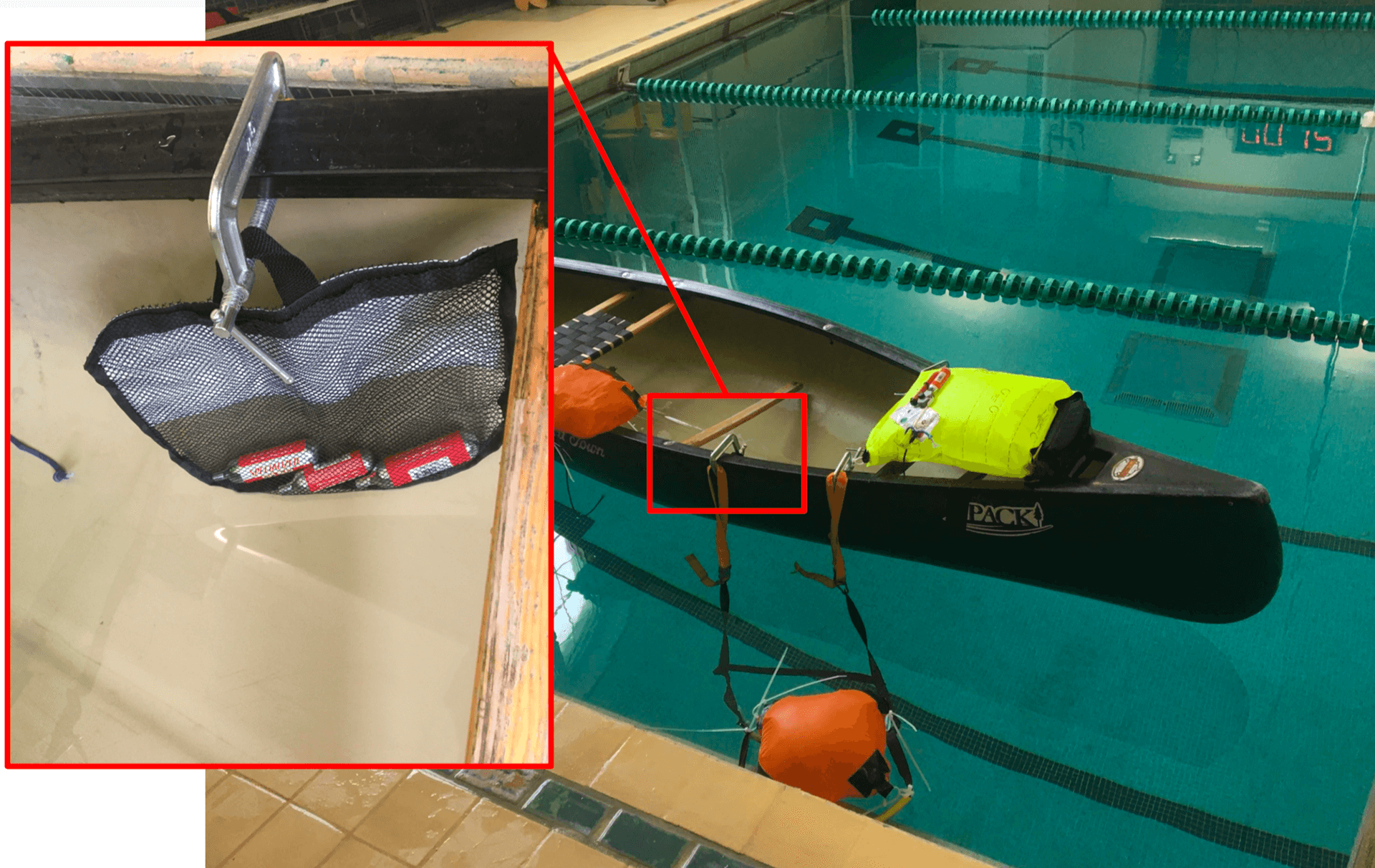

Lever prototype

We iterated on the design of the ladder during pool testing. First, we tried a lever mechanism that was attached to a rope on the ladder in an attempt to provide counterbalance. Unfortunately, this did not produce the desired effect and climbing back in was still difficult.

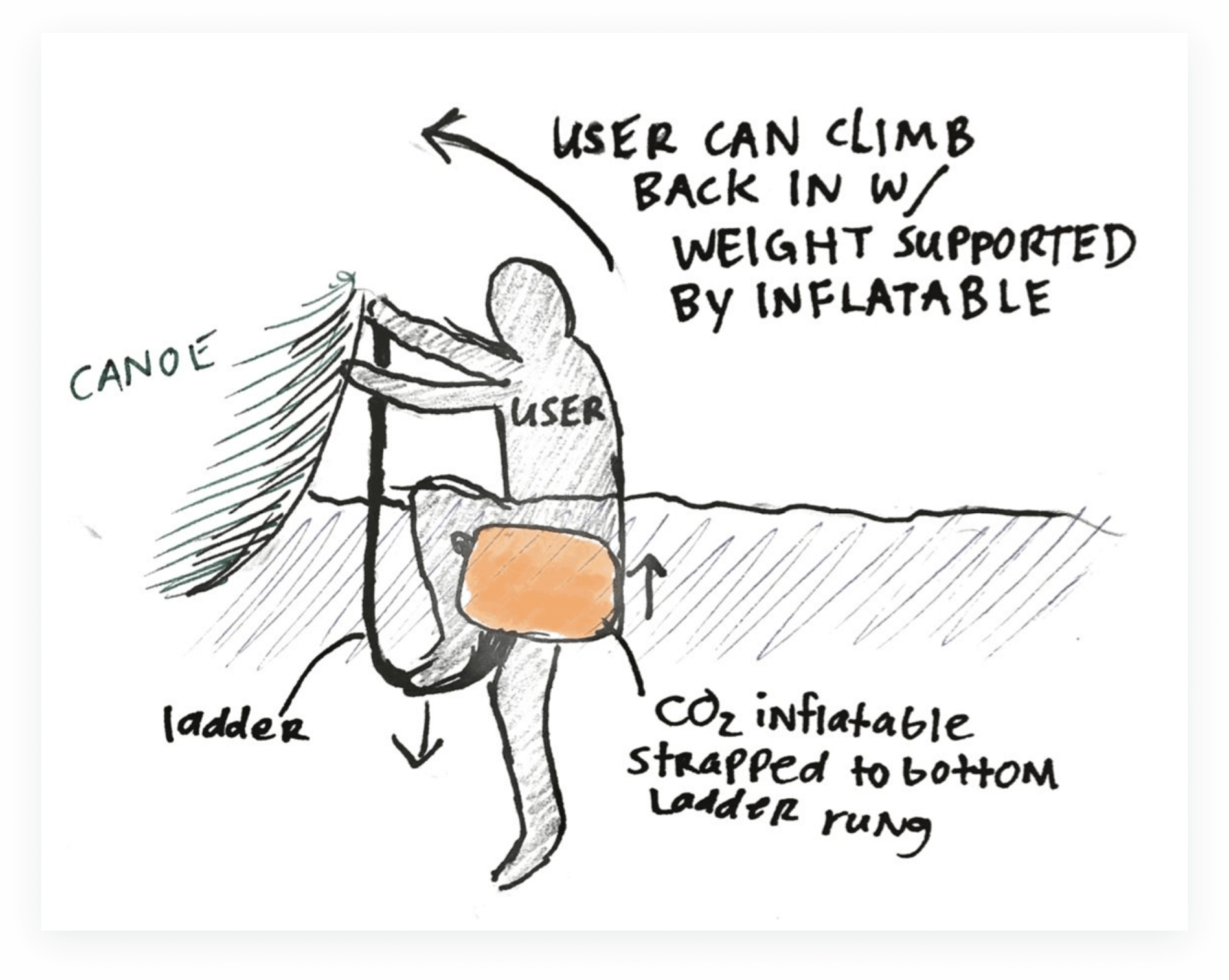

Float prototype

This ladder with a CO2 inflatable attached to the end provides support to the user when they step down on the upper rungs. The buoyant inflatable helps boost them up and climb into the canoe without pulling down on the side of the boat and causing it to flip again.

We tested this design with the inflatable on different rungs, various ladder lengths, and multiple inflatables. Ultimately, a single inflatable on the bottommost rung gave sufficient support and was easiest for the user to deploy.

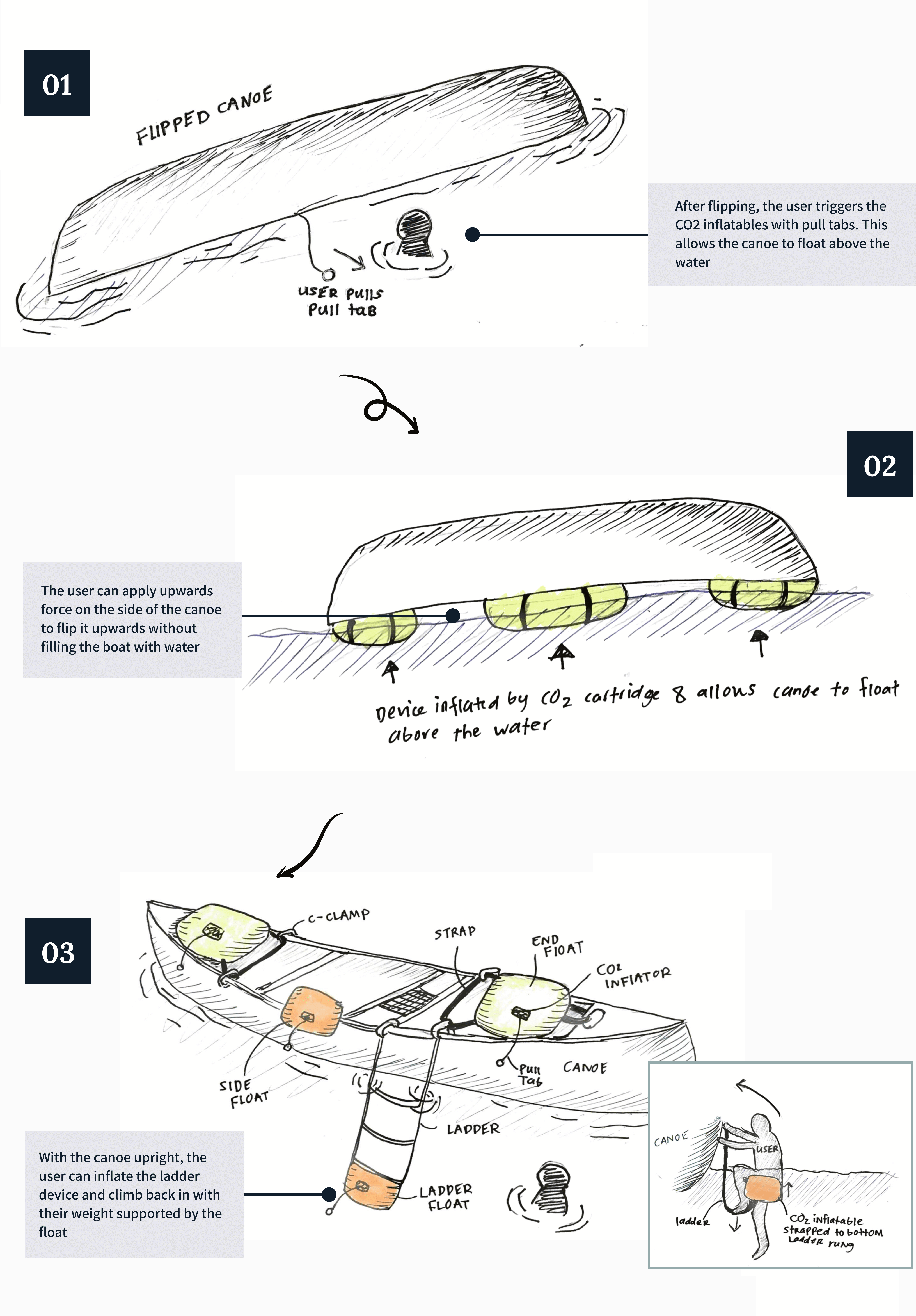

USER FLOW

FINAL PROTOTYPE

Un-flipping demo

Re-entry demo

TESTING

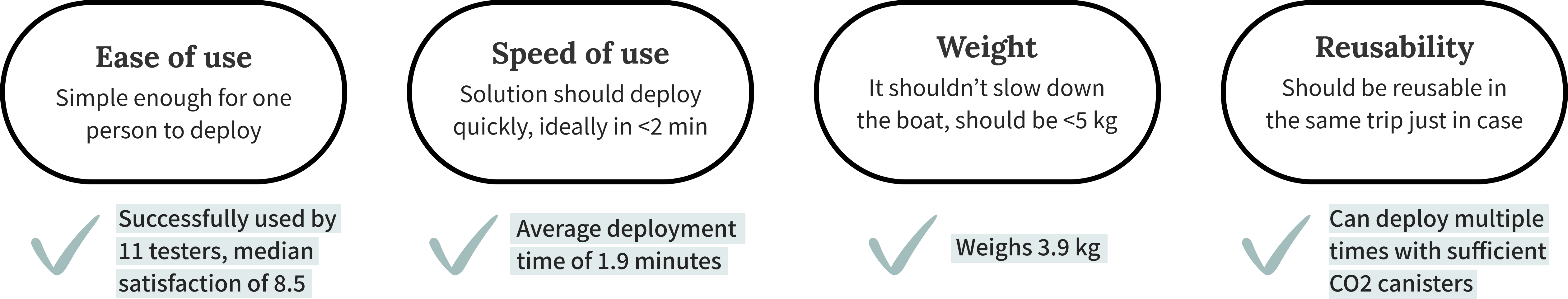

Ensuring specifications were met using data

After building our prototype, we needed to test it with users to make sure it met our specifications. We also measured its performance in comparison to two state of the art products/techniques.

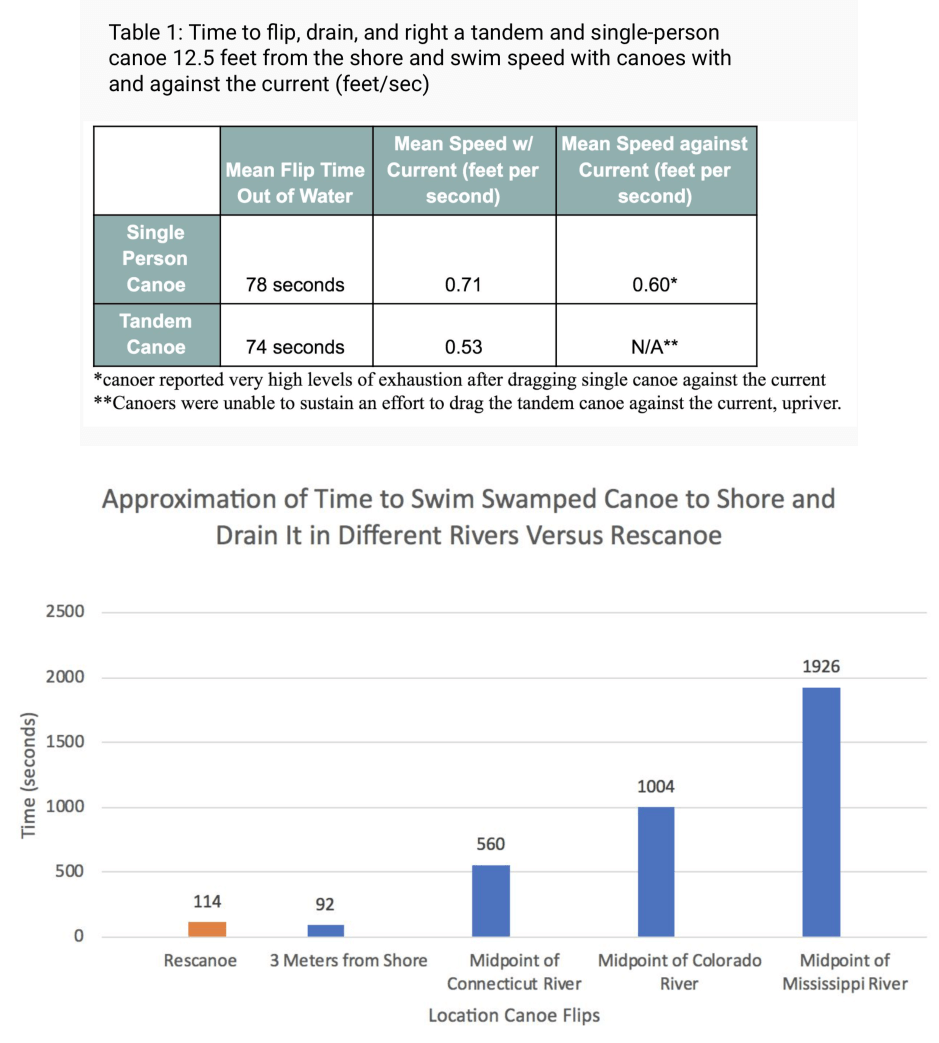

Speed of use testing

We were not granted access to the pool until the last week of the term, and so on a 45-degree New Hampshire afternoon we donned wetsuits in the name of data collection.

By recording the average swim speed of an individual dragging a canoe (to mimic dragging a capsized canoe to shore), we were able to extrapolate it to different distances.

While dragging a canoe from the midpoint of a large river like the Mississippi could take upwards of 32 minutes, using Rescanoe took an average of 1.9 minutes. This would remain constant no matter the size of the river.

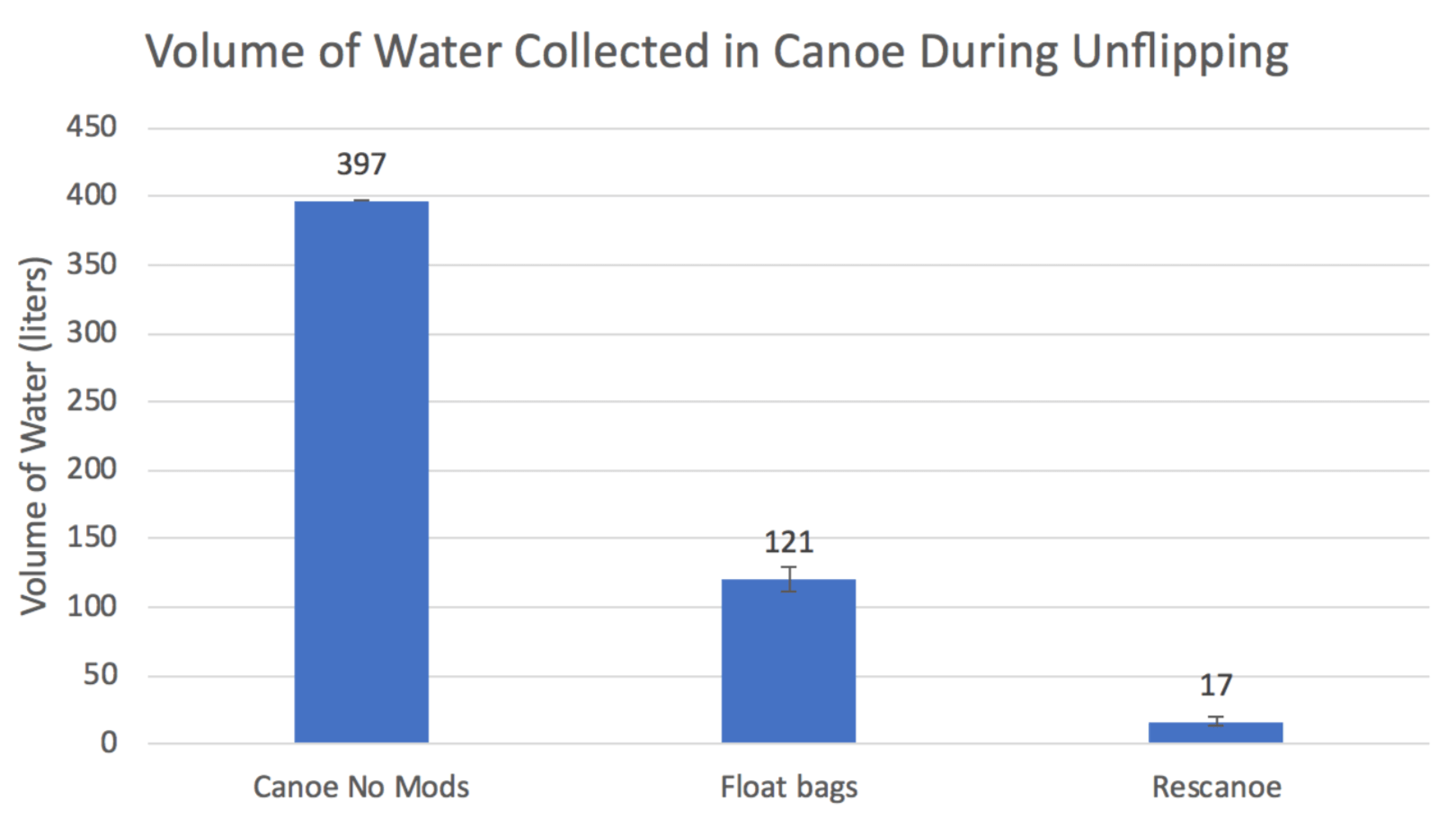

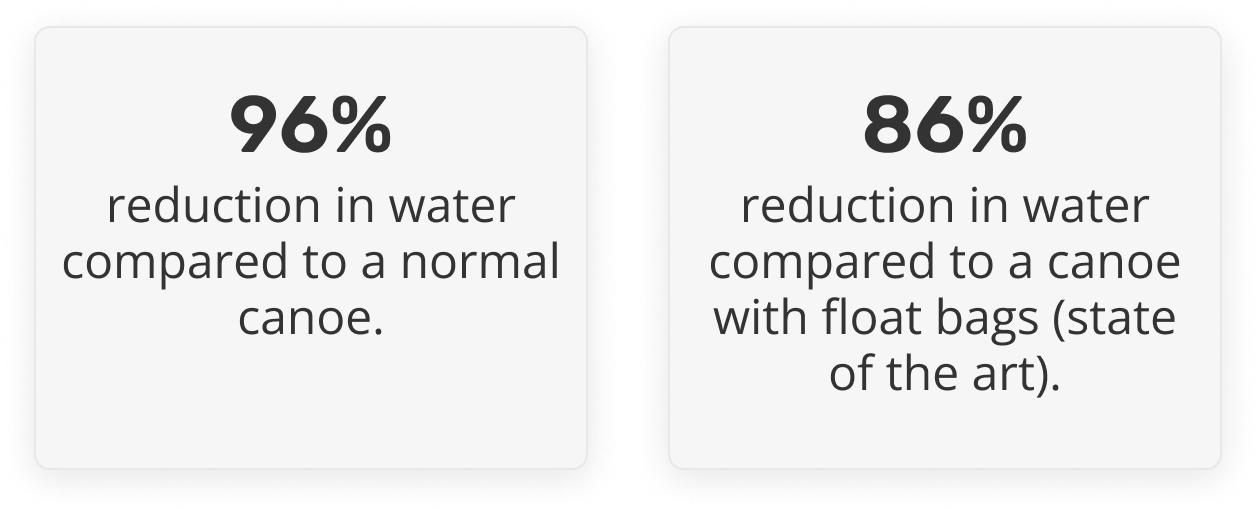

Swamp testing

We wanted to ensure that Rescanoe could effectively drain most water from the canoe after the user un-flips it. We capsized a canoe with no modifications, float bags, and Rescanoe to compare performance, and found that Rescanoe is effectively empties the water from a capsized canoe.

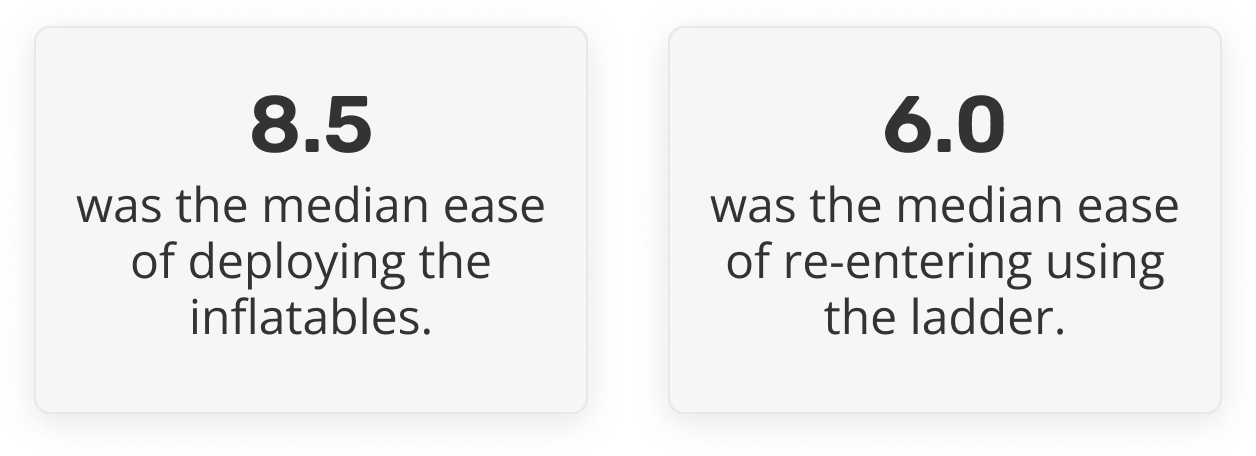

Qualitative ease of use testing

11 users tried using Rescanoe and ranked how easy they found deploying the device and using the ladder on a scale of 1-10 (10 being easiest).

The ladder definitely presented the most difficulty for our users and has ample room for improvement, however many still reported that it was "better than nothing" (10/11 users failed to re-enter the canoe with no assistive device).

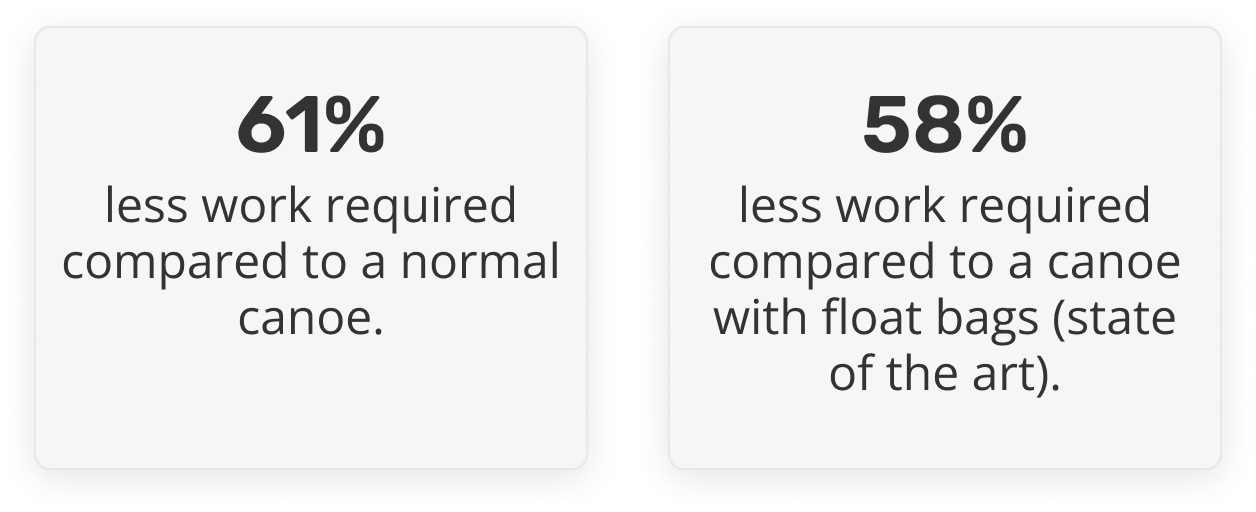

Quantitative ease of use testing

We calculated the work (force*distance) required to un-flip a canoe with no modifications, a canoe with state of the art float bags, and a canoe with Rescanoe.

It takes less strength and effort to un-flip a canoe using Rescanoe than with conventional methods.

WRAP UP

Returning to the key specifications, how did Rescanoe perform?

Rescanoe performed significantly better than the state of the art in all of the tests that we conducted, but of course there is always more work to be done. With more time, we would want to improve upon the design of the ladder to make it more stable and user-friendly.

Future iterations could also explore the use of connected inflatables that are triggered with one pull cord, better aesthetics, and adaptation to other types of boats (skulls, fishing boats, etc.).

OUTCOME

After presenting Rescanoe to a committee of instructors, our group was awarded a citation for academic excellence. We filed a U.S. provisional patent in May 2019

TAKEAWAYS

#1

Getting physical comes with new challenges

Rescanoe was one of the most difficult, yet most rewarding, projects I've worked on. Diving into the realm of physical product design and engineering was relatively new for me, and there were lots of interesting challenges that I hadn't encountered in digital design. For example, prototyping and iterating is less agile when working with a physical product. I found that sticking to a project timeline, staying organized, and leaving lots of time for tinkering were important for success.

#2

Hands-on engineering skills

I also learned so many new tools to help "think with my hands." This class taught me CAD, 3D printing, milling/lathing, laser cutting, and lots more so that we could get out there and start creating. Making prototypes that help users visualize and interact with our ideas was the most effective way to gain constructive insights, and ENGS 21 gave me the skills and confidence to do that.

#3

The Connecticut River is very cold in October

This one speaks for itself. If I were to do this all again, I would have definitely pushed to get pool access earlier on...

NCSECU StorefrontUX/UI • Client work

FlourishUX/UI • Student work

TD WealthUX/UI • Client work

Magellan EAP AppUX/UI • Client work

GoPhishUX/UI • Student work

The Imagination StationExperience design • Student work

UnioUX/UI • Student work